Our Story

-

2005 Born Redstamp for the cutting tools construction and production of related products..

-

2009 Redstamp become a supplier of molds and prototypes for BMW - born crash test center on Castelmarte (CO).

-

2011 Transferring in a 1500 square meters of new factory site in Macherio (MB), where was extend the numbers of milling machines and where is it set up a special department for finite element analysis (simulation of plastic injection molding and sheet metal, structural analysis and crash simulations)

-

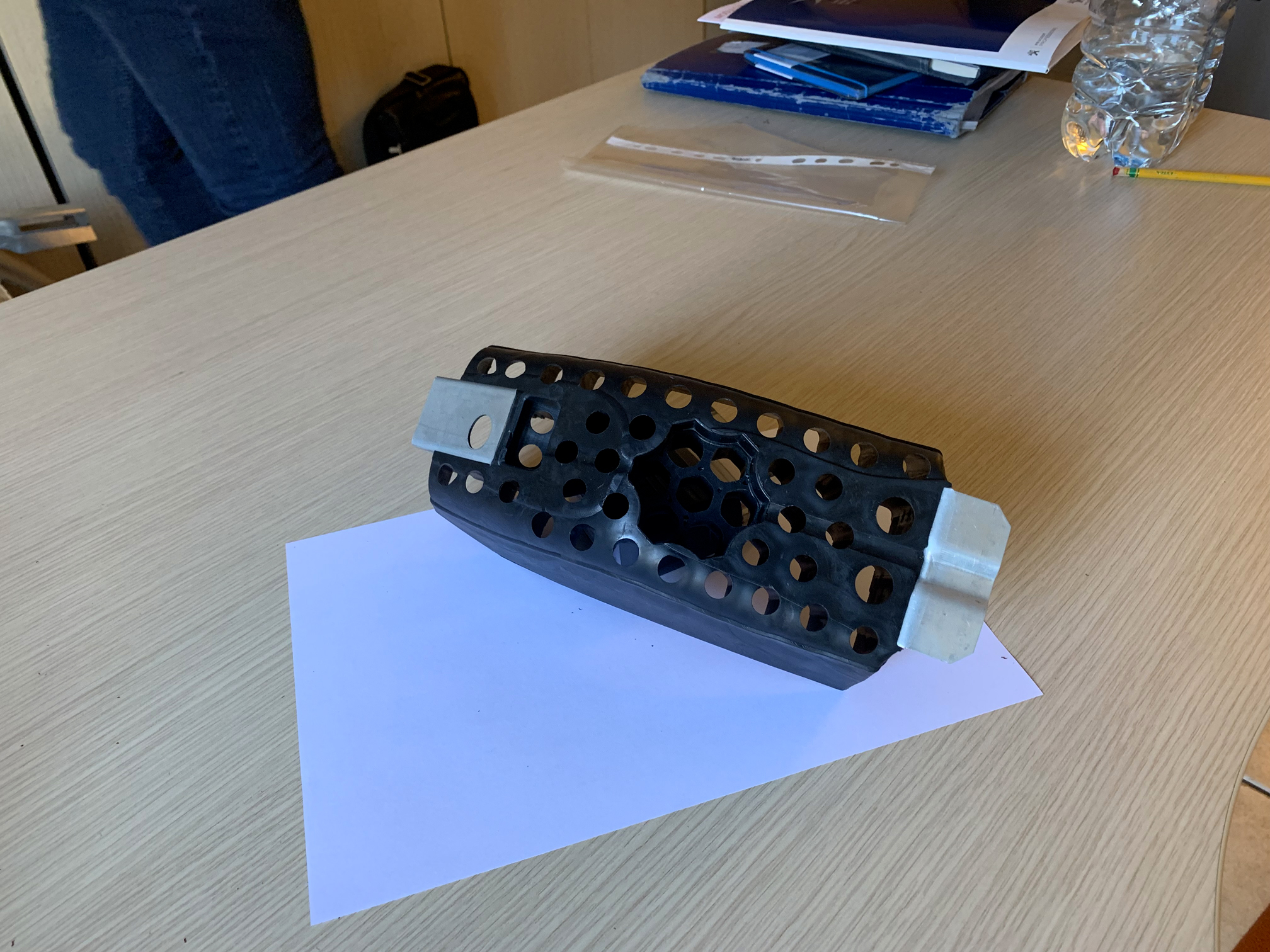

2014 Designed and construct of the first body in white molded reinforcements and started the study of first plastic reat floor impact-resistant for USA rear crash (at 80km/h)

-

2015 Transferring in a 2500 square meters of new factory site in Lissone (MB) where was increased and modernized the safety center

-

2017 Implementing of molding production area in order to do trial tools and little molded parts productions.

-

2018 patenting of new full steel bumper beam concept , that link the cost advantage of the steel with lightness reached with an innovative system of shape and the welding method.

-

2019 – 2020 identified as Expert developers for the energy dissipation systems of the PSA group. Start of Front and rear crash boxes , beam and absorber structures development for PSA group

Technical Office

The technical office has a surface of 150m2 divided by more location , divisible on more other locations if necessary by clients.It's Possible To Do More Work Platform And To Do Meeting Into The Specifics Meeting Rooms.

We Constantly Improve The Workshop In Order To Always Have The Best Equipment And to Be Able To Obtain Better Results In Terms Of Tolerance And Reliability.

Into The Mechanical Workshop We Can build :

-

Stamping Tools (For Plastic , Thermoplastic, Co-stamping Sheet Metal And Plastic, Sheet Metal And More)

-

Welding Tools (Like Hot Blade Welding Automatic Machine)

-

Prototype Tools And Finished Products

In Order To Improve The Correlation Between The Experimental Data And Numerical Results Redstamp Srl Has Developed Its Own Internal Testing Center. The Workshop Includes The Following Equipment:

-

New Image Color Camera, High Speed 1000fps 800x600pixel

-

Load Cells And Accelerometers

-

Laser Sensors For Displacement Measurement

-

Weight Balance

-

2 Cars Simulator (Trolley) Equipped With Fittings Compatible Multiple

-

Ece42 An Std 581pendulum

-

Crash Launch Sistem For Speeds Up To 48km / H (Azt, Bumper Test, Post, Etc. ..)

-

Rigid Wall Compatible With The Installation Of Azt Barrier , Bumper Test , Pole And Deformable Barrier

-

Drop Test Equipment For Test On Components With Load Cells

-

Dynamometer For Measuring The Mechanical Properties Of Materials

-

Data Processing Software